IoT Product Engineering and Embedded Systems Development: PCBA and EMS Scale-up for High-Current Pulse Drivers

Introduction: The Challenge of Scaling Complex Power Electronics

High-current, short-duration pulse drivers require special handling, including precise timing, controlled pre-charge, EMI control, and robust test coverage. Lab prototypes often fail on the production line due to obscure manufacturing tolerances, demanding expert IoT product engineering to ensure safety and yield at scale.

Solution Overview: Production-Ready PCBA with Robust QC

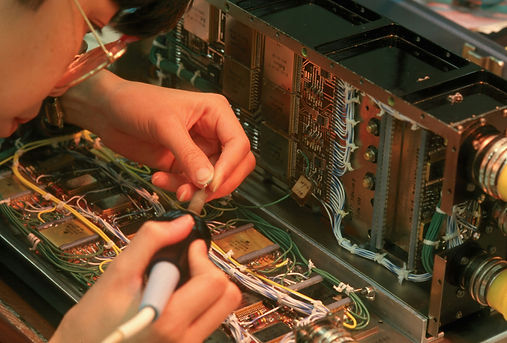

EurthTech translated a complex lab topology (boost stage + capacitor bank + fast switching FETs) into a repeatable PCBA (Printed Circuit Board Assembly) and test-fixture set. We reworked the PCB stack-up for low inductance and implemented a rigorous two-stage ICT (In - Circuit Test) sequence and functional burn-in. This systematic approach ensures predictable yield and repeatable pulse performance, a critical foundation for any high-power embedded systems development.

Technical Implementation: Dfx, Test Automation, and Embedded AI India

The design followed DFx (Design for Excellence) principles: adding Kelvin sense traces, implementing creepage/clearance for safety, and using snubbers and RC damping to control EMI. The functional test fixture used automated comparator scripts to validate pulse amplitude, rise/fall times, and capacitor balancing. We developed an EMS - ready BoM with defined component qualifiers (ESR tolerance, FET thermal resistance) and specific assembly SOPs, showcasing the manufacturing maturity of our Embedded AI India team.

Results & Impact: Operational ROI and Quality Improvement

Pilot production runs resulted in an initial yield improvement from ~70% to ~92% after two rework cycles. We reduced test-time per unit to ~3.5 minutes while maintaining full coverage. EMI suppression and mechanical decoupling solved earlier field-failure modes, and test data established statistical process control charts. This successful scale-up reduced field failures and improved MTBF (Mean Time Between Failures) estimates, providing significant operational ROI.

Scalability & GIS Context: The project provided the full EMS onboarding package and ICT automation scripts needed for volume production. The high-current pulse driver, often used in industrial lighting or laser systems, is a key component within a broader Predictive maintenance AI IoT network. Ensuring the reliability and scale of such critical hardware is foundational to delivering any large-scale smart infrastructure solution.