Comprehensive Insights into Electronics Manufacturing Services

- Eurth Engineering

- Nov 2, 2025

- 4 min read

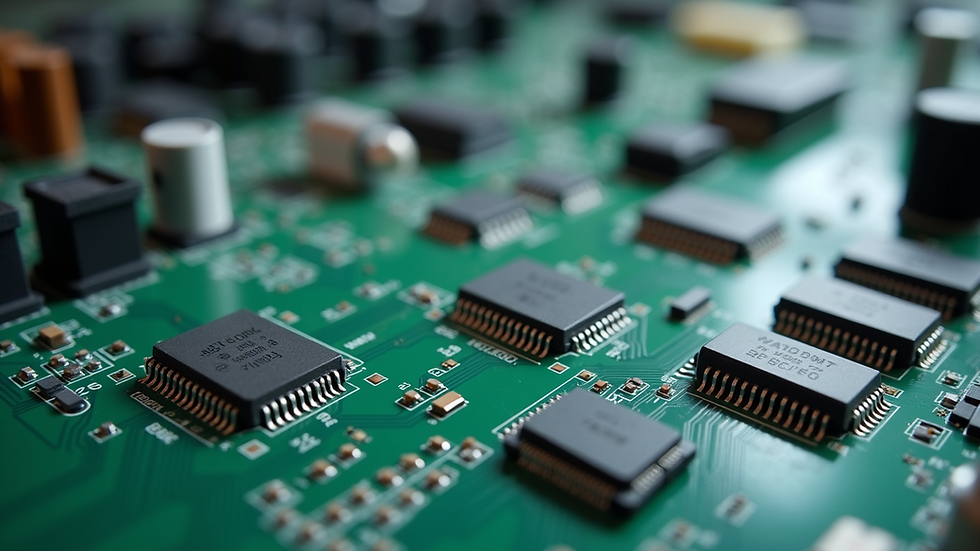

In today's fast-paced technological world, the demand for high-quality electronic products is ever-increasing. Behind every innovative gadget, device, or system lies a complex process of design, assembly, and testing. This is where electronics production services play a crucial role. These services ensure that electronic components and devices are manufactured efficiently, reliably, and at scale. This article delves deep into the world of electronics production services, offering practical insights and actionable recommendations for businesses and enthusiasts alike.

Understanding Electronics Production Services

Electronics production services encompass a wide range of activities involved in the creation of electronic products. These services include everything from printed circuit board (PCB) assembly to final product testing and packaging. The goal is to transform raw materials and components into fully functional electronic devices ready for the market.

Key Components of Electronics Production Services

PCB Assembly: This involves mounting electronic components onto a PCB. It can be done through surface-mount technology (SMT) or through-hole technology.

Testing and Quality Control: Ensuring that each product meets the required specifications and functions correctly.

Prototyping: Creating initial versions of a product to test design concepts and functionality.

Supply Chain Management: Coordinating the procurement of components and materials to ensure timely production.

Final Assembly and Packaging: Putting together all parts and preparing the product for shipment.

By outsourcing these tasks to specialized providers, companies can focus on innovation and marketing while ensuring their products are manufactured to the highest standards.

The Role of Electronics Production Services in Modern Manufacturing

Electronics production services have become indispensable in the manufacturing sector. They offer several advantages that help businesses stay competitive and meet market demands.

Benefits of Using Electronics Production Services

Cost Efficiency: Outsourcing production reduces the need for heavy capital investment in manufacturing facilities and equipment.

Expertise and Technology: Specialized providers have access to the latest manufacturing technologies and skilled personnel.

Scalability: Production can be scaled up or down based on demand without affecting the core business operations.

Faster Time-to-Market: Streamlined processes and experienced teams help reduce production lead times.

Quality Assurance: Rigorous testing and quality control ensure product reliability and customer satisfaction.

For example, a startup developing a new wearable device can leverage electronics production services to prototype, test, and manufacture their product without building an in-house factory. This approach accelerates development and reduces risks.

What does EMS mean in manufacturing?

EMS stands for Electronics Manufacturing Services. It refers to companies that provide comprehensive manufacturing solutions for electronic products. These services cover the entire production lifecycle, from design support and prototyping to mass production and after-sales support.

Key Functions of EMS Providers

Design for Manufacturability (DFM): Advising on product design to optimize manufacturing efficiency and reduce costs.

Component Sourcing: Procuring high-quality components from reliable suppliers.

Assembly and Testing: Using advanced machinery and techniques to assemble and test products.

Logistics and Distribution: Managing inventory, packaging, and shipping to ensure timely delivery.

EMS providers act as strategic partners, helping businesses navigate the complexities of electronics manufacturing. They bring expertise, resources, and flexibility that are often beyond the reach of individual companies.

Choosing the Right EMS Partner

When selecting an EMS provider, consider the following factors:

Experience and Reputation: Look for providers with a proven track record in your product category.

Technological Capabilities: Ensure they have the necessary equipment and expertise.

Quality Certifications: Check for industry-standard certifications like ISO 9001 or IPC standards.

Location and Logistics: Proximity to your market or supply chain can reduce costs and lead times.

Customer Support: Responsive communication and after-sales service are critical.

By partnering with the right EMS provider, companies can enhance product quality, reduce costs, and accelerate innovation.

Practical Tips for Optimizing Electronics Production Services

To maximize the benefits of electronics production services, businesses should adopt best practices throughout the product lifecycle.

Design Phase

Incorporate DFM Principles: Design products with manufacturing constraints in mind to avoid costly revisions.

Use Standard Components: This simplifies sourcing and reduces lead times.

Collaborate Early with EMS Providers: Engage manufacturers during the design phase to leverage their expertise.

Production Phase

Implement Rigorous Testing: Use automated and manual testing to catch defects early.

Monitor Supply Chain Risks: Maintain good relationships with suppliers and have contingency plans.

Optimize Production Scheduling: Balance capacity and demand to avoid bottlenecks.

Post-Production Phase

Track Quality Metrics: Analyze defect rates and customer feedback to improve processes.

Plan for Scalability: Ensure the EMS provider can handle volume increases.

Maintain Clear Communication: Regular updates and transparency help prevent misunderstandings.

By following these recommendations, companies can ensure smooth production cycles and high-quality outputs.

Future Trends in Electronics Production Services

The electronics manufacturing landscape is evolving rapidly, driven by technological advancements and changing market needs.

Emerging Technologies

Industry 4.0: Integration of IoT, AI, and automation in manufacturing processes for smarter production.

Additive Manufacturing: 3D printing of electronic components and enclosures for rapid prototyping and customization.

Sustainable Manufacturing: Eco-friendly materials and processes to reduce environmental impact.

Market Dynamics

Increased Demand for Customization: Consumers want personalized products, pushing manufacturers to adopt flexible production methods.

Global Supply Chain Shifts: Geopolitical factors and trade policies are influencing sourcing and manufacturing locations.

Focus on Quality and Compliance: Stricter regulations require manufacturers to maintain high standards.

Staying informed about these trends will help businesses and EMS providers adapt and thrive in a competitive environment.

Electronics production services are the backbone of modern electronic product development and manufacturing. By understanding their scope, benefits, and best practices, companies can make informed decisions that drive innovation and success. Whether you are launching a new product or scaling an existing one, leveraging professional electronics manufacturing services can be a game-changer in achieving your business goals.

Comments