Why Automotive Startups Struggle With ISO 26262 – And How Smart Teams Shortcut Certification With Free Tools

- Srihari Maddula

- Nov 11, 2025

- 3 min read

Updated: Nov 14, 2025

Electric vehicles, ADAS systems, e-bikes, battery management systems, and autonomous shuttles all share one non-negotiable requirement — functional safety.

Safety isn’t a checkbox. It’s a culture.

When a battery pack overheats, a steering ECU resets mid-turn, or a brake controller misreads a sensor, lives are at stake. The guiding principle of automotive design remains simple:

“When it fails, it must fail safely.”

That’s the essence of ISO 26262, the global functional safety standard for automotive systems.

But here’s what most founders learn after spending lakhs on redesigns:ISO 26262 isn’t about expensive hardware — it’s about process, diagnostics, and proof.

Understanding ISO 26262 Without Drowning in Terminology

At its core, ISO 26262 asks you to:

Identify hazards

Analyze risks

Assign severity → ASIL (A–D)

Design detection and reaction mechanisms

Prove and document the results

Free resources to start:

ISO 26262 Public Summaries (Free PDFs)

ASIL Determination Checklists (Excel templates)

Automotive SPICE Guides for software maturity

NHTSA Safety Notes for practical examples

These are enough for any IoT product engineering or embedded systems development team to draft a credible Safety Plan before writing a single line of firmware.

Free Training That Turns Engineers into Safety Experts

You don’t need expensive consultants to understand ISO 26262.

Excellent, free courses exist:

MIT OCW – Safety Engineering

Texas Instruments Functional Safety Training (lockstep cores, watchdogs, ECC)

NXP SafeAssure Tutorials

YouTube lectures explaining ASIL and safety design

With 2–3 weeks of structured learning, a small embedded development team becomes safety-literate enough to architect compliant systems from Day 1.

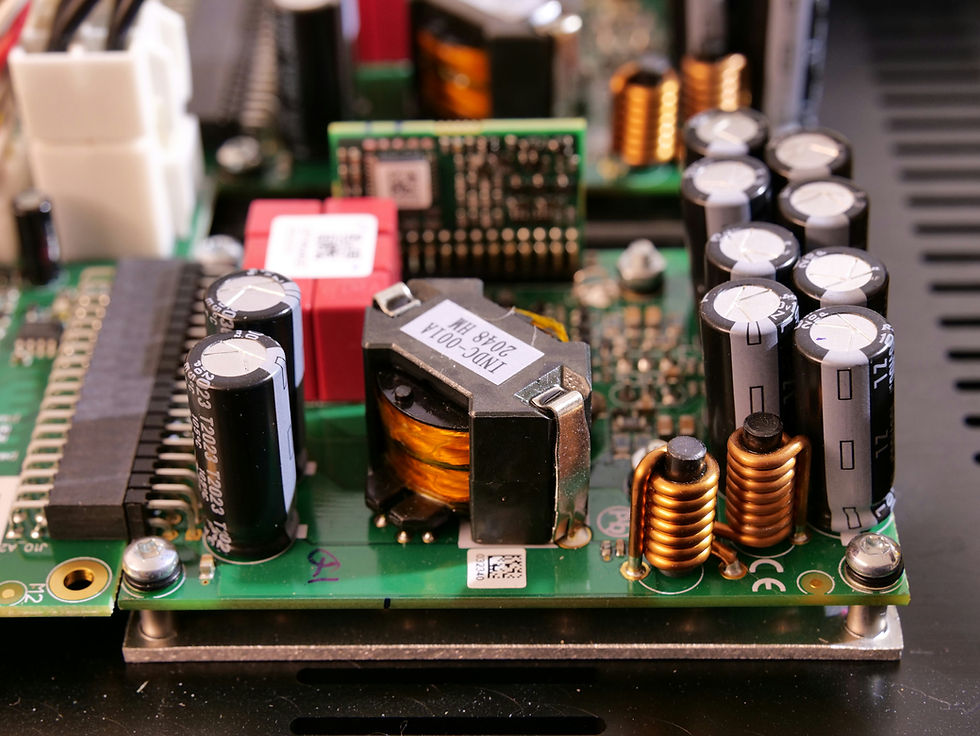

The Silicon Already Supports ASIL — If You Use It Correctly

Modern automotive MCUs are built with safety in mind — the problem is, most firmware ignores these features.

Examples:

TI Hercules: lockstep cores, ECC, BIST

Infineon AURIX: triple lockstep + crypto

NXP S32: memory protection, diagnostics

Renesas RH850: powertrain-grade safety MCU

Each provides free safety manuals and design guides on:

CRC and self-tests

Boot-time diagnostics

Safe-state transitions

Peripheral isolation

For AI-powered embedded systems and Industrial IoT controllers, activating these built-in diagnostics is often the difference between a first-time pass and an audit failure.

Diagnostics & UDS – Making ECUs Explain What Went Wrong

Functional safety doesn’t stop at hardware — it extends to communication and serviceability.

When faults occur, the ECU must detect, log, react, and report the event. That’s what UDS (ISO 14229) enables.

Open tools for diagnostics:

UDS Open Implementations (GitHub)

SavvyCAN – visual CAN analyzer

python-can / can-utils – simulate and replay fault frames

CANtact – open-hardware CAN interface

These allow IoT & embedded services India teams to build diagnostic-ready ECUs without expensive toolchains.

Safety Isn’t Just Hardware — It’s Documentation

Every serious automotive product must deliver four key documents:

Safety Case

Safety Requirements Traceability Matrix

Safety Manual

Free templates and community toolkits exist for each, helping startups eliminate the biggest barrier to compliance — documentation quality.

This process discipline translates directly into end-to-end embedded product design maturity.

Fault Injection and Virtual Testing

You don’t need to crash vehicles to test safety logic. Open-source tools let you simulate realistic failures:

OpenFTA – Fault Tree Analysis for ISO 26262

QEMU ECU Emulation – virtual fault testing

Open Fault-Injection Repos – reproducible safety validation

By virtualizing these tests, teams can validate Edge AI embedded systems, battery controllers, and ADAS units quickly, saving months of physical testing time.

Automotive Cybersecurity Is Now Mandatory

Safety and security are now inseparable. UN Regulations R155 & R156 demand:

Secure boot

Signed OTA updates

Encrypted in-vehicle communications

Vulnerability handling lifecycle

Free resources:

UN R155/R156 PDFs

ETSI EN 303 645 – Cybersecurity Baseline

OWASP Automotive Security Guidance

In AI for smart infrastructure and connected EV ecosystems, cybersecurity is as critical as functional safety.

What This Means for Startups

You don’t need a 50-person safety department. You need architecture, process, and the right partner.

At EurthTech, we help teams:

Design ASIL-compliant electronics and firmware

Conduct hazard and risk analysis (HARA)

Integrate safety MCUs (AURIX, Hercules, RH850, S32)

Implement UDS, diagnostics, and CAN/LIN/FlexRay stacks

Generate DFMEA, traceability matrices, and safety cases

Prepare for ISO 26262 and Automotive SPICE audits

Build OTA + cybersecurity pipelines for R155 compliance

With our AI product engineering company India expertise, we blend smart infrastructure solutions and automotive-grade safety to help startups bring certified products to market faster.

Because when safety is built in from the start, certification becomes documentation — not a redesign.

Building Safe Mobility for a Connected Future

Whether you’re developing EV platforms, ADAS controllers, BMS units, or telematics ECUs, EurthTech’s engineering services for smart cities and digital transformation for infrastructure empower you to design with confidence — and certify without compromise. Need expert guidance for your next engineering challenge?Connect with us today — we offer a complimentary first consultation to help you move forward with clarity.

Comments